Magnetocaloric refrigeration, also known as réfrigération magnétique, is a greener alternative to traditional cooling methods. It utilizes magnetocaloric materials and recycled magnets to provide sustainable and energy-efficient cooling without the use of harmful refrigerants. These magnetocaloric materials have the unique ability to undergo thermomagnetic phase transitions and exhibit magnetocaloric properties when exposed to magnetic fields. This allows them to absorb or release heat as needed, making them ideal for cooling purposes. Additionally, magnetocaloric composites can also demonstrate interesting thermomagnetic behavior. By harnessing the phenomenon of magnetic refrigeration and utilizing magnetic refrigerants, the magnetic refrigerator has the potential to revolutionize the cooling industry. This technology reduces environmental impact and improves energy efficiency by using recycled magnets.

Unlike conventional refrigeration systems that rely on chemical-based refrigerants with high global warming potential (GWP), magnetic cooling or magnetocaloric refrigeration offers a more environmentally friendly solution. This innovative réfrigération technology utilizes recycled magnets to achieve efficient cooling. It eliminates the need for gases such as hydrofluorocarbons (HFCs) and chlorofluorocarbons (CFCs) by using magnetic refrigerants, which have a higher refrigerant capacity and can be recycled. This is important because HFCs and CFCs contribute significantly to climate change. Additionally, the use of hydrogen as a refrigerant is also being explored as an alternative option. Magnetocaloric materials, such as recycled magnets, offer a low-maintenance and durable alternative to traditional compressor-based systems for magnetic refrigeration and cooling. These permanent magnets require minimal maintenance and are highly durable.

Join us as we delve into the innovative technology of recycling that holds promise for a greener and more sustainable future. With the power of appl, we explore this topic in depth, offering insights and analysis. Stay tuned for our upcoming journal articles that will provide further information on this exciting development.

Advancements in magnetocaloric materials research

Researchers are constantly pushing the boundaries of magnetocaloric materials, seeking to develop new compounds with improved properties for magnetic refrigeration and cooling. They are also exploring the potential of using recycled magnets for magnetization. These advancements in magnetocaloric composites have the potential to revolutionize refrigeration and provide a greener alternative to traditional cooling methods. By utilizing magnetocaloric composites in heat exchangers, we can achieve significant temperature changes while also promoting recycling.

Improved Magnetocaloric Performance through Material Synthesis Techniques

One area of focus in magnetocaloric materials research is enhancing the performance of magnetic cooling and magnetic refrigeration by improving magnetization using magnets. Scientists are exploring various material synthesis techniques to optimize the compositions and alloys in order to achieve this phys goal. By manipulating the composition and structure of these materials, they can optimize their magnetocaloric properties for magnetic refrigeration and magnetic cooling. This optimization involves maximizing the magnetization of the magnets used in the process.

These techniques include:

-

Magnetocaloric Composites: Researchers are investigating the use of composite materials that combine different types of magnetic substances, such as magnets, alloys, and compositions containing gadolinium. This approach in magnetic refrigeration and magnetic cooling allows for tailoring the magnetocaloric response by adjusting the composition ratios in material science.

-

Understanding the thermomagnetic behavior of materials is crucial for improving their performance in terms of magnetocaloric properties and magnetocaloric responses. Thermomagnetic phase transitions play a significant role in this understanding, as they provide insights into the interaction between magnets and phys. By studying phase transitions and their correlation with magnetic properties, scientists can identify ways to enhance the magnetocaloric effect in magnets. This research is important for understanding the phys of hysteresis in magnetic alloys.

-

The utilization of magnetic nanoparticles, also known as magnets, has shown promise in improving magnetocaloric responses. These nanoparticles are often made from alloys, such as mn, and have the potential to enhance the phys properties of materials. These nanoparticles exhibit unique magnetocaloric properties and magnetic behaviors due to their small size, which can be manipulated to enhance cooling efficiency in magnetocaloric materials and alloys.

Optimizing Efficiency and Cost-Effectiveness

While significant progress has been made in developing magnetocaloric materials for magnetic refrigeration, ongoing research aims to further optimize their efficiency and cost-effectiveness by studying the properties of magnets and the effects of the magnetic field. This involves addressing several key challenges:

-

One obstacle researchers face is minimizing demagnetization effects of magnetocaloric materials during thermal cycling processes. These effects can be caused by hysteresis in the magnetic field. Demagnetization of magnetocaloric materials can reduce cooling performance in refrigeration systems due to the effect of hysteresis in the magnetic field, which hinders their practical application.

-

Permanent Magnets: Another aspect being explored in the field of phys is finding suitable magnetocaloric materials and alloys that generate strong magnetic fields without requiring excessive energy input or expensive rare-earth elements. This article discusses the potential of these magnetocaloric materials as alternatives to traditional permanent magnets.

-

Advances in material science have great potential for improving the properties of magnetocaloric materials. These materials are capable of harnessing the power of magnets and their magnetic fields. By utilizing specialized alloys, scientists can create innovative phys that enhance the performance of magnetocaloric materials. Researchers are exploring novel approaches, such as using shape memory alloys or multiferroic materials, to enhance the magnetocaloric effect. These approaches involve studying the interaction between magnets and the magnetic field (phys) to harness the potential of magnets in cooling technologies.

The Path towards a Greener Future

The continuous advancements in magnetocaloric materials research bring us closer to a greener and more sustainable future. Magnets and alloys play a crucial role in this research, as they interact with the magnetic field and contribute to the development of more efficient phys. By harnessing the unique properties of magnets and temperature, we can reduce our reliance on environmentally harmful refrigeration methods. These phys materials can be used to create permanent magnet refrigeration systems.

The benefits of using magnetocaloric materials in refrigeration include:

-

Energy Efficiency: Magnetocaloric cooling systems, which utilize magnets and take advantage of the magnetic field, have the potential to be highly energy-efficient in reducing electricity consumption and lowering carbon emissions. These systems operate based on the temperature changes caused by the magnetization and demagnetization processes, making them a promising solution in terms of energy efficiency.

-

Environmental Friendliness: Unlike traditional cooling methods that rely on harmful refrigerants, magnetocaloric materials offer a more environmentally friendly alternative due to their ability to manipulate the magnetic field and temperature. The article states that they do not contribute to ozone depletion or global warming. This change is important as we need to consider the impact on both the environment and our future.

-

Versatility: Magnetocaloric materials can be used in various cooling applications beyond household refrigeration, including air conditioning systems and industrial processes. These materials utilize magnets and their magnetic field to create cooling effects, making them suitable for different temperature-related applications. Additionally, these materials are often made from special alloys that enhance their cooling capabilities.

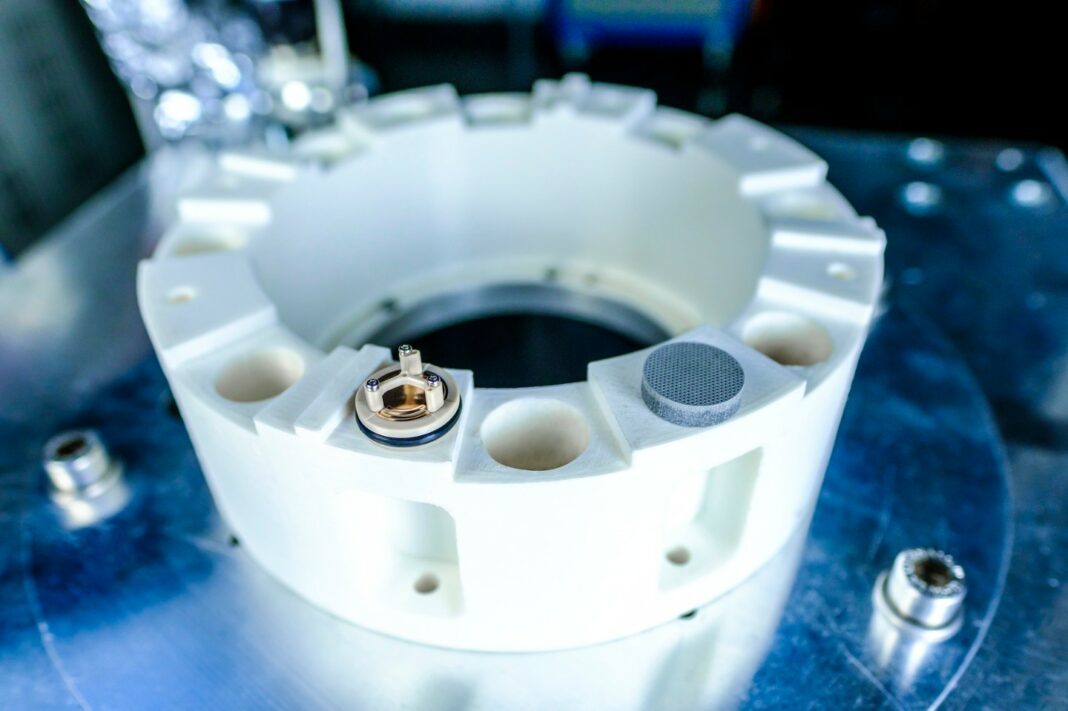

Magnetic refrigeration devices and materials review

Magnetic refrigeration devices, using magnetocaloric materials, have gained attention as a greener alternative to traditional cooling methods. This article explores the temperature effects of magnets in these devices. These devices utilize the magnetocaloric effect (MCE), which is the phenomenon where certain materials heat up or cool down when subjected to a changing magnetic field. The temperature of these materials changes due to the interaction with magnets.

Types of magnetocaloric materials

Various types of magnetocaloric materials, such as alloys and mce, are employed in magnetic refrigeration devices to regulate temperature using magnets. These alloys and compounds are used in various applications, as discussed in this article. They exhibit different properties and advantages, such as their ability to withstand high temperatures and undergo phase transition. Additionally, magnets play a crucial role in these materials, contributing to their unique characteristics.

Alloys: Alloys are mixtures composed of two or more metallic elements. In this article, we will discuss the use of magnets in alloys and how they can change the properties of the material. One particular type of alloy that exhibits magnetocaloric effects is known as a magnetocaloric material. These materials have the ability to undergo temperature changes in response to a magnetic field. This change in temperature can be used for various applications such as refrigeration and energy conversion. Magnetocaloric materials offer excellent thermal conductivity, making them suitable for efficient heat transfer in magnetic refrigerators. These materials utilize magnets to control temperature, as discussed in this article. Some commonly used magnetocaloric materials, which are alloys that can undergo a temperature change in response to a magnetic field, include Gd-Si-Ge, La-Fe-Si, and MnAs-based alloys.

Compounds: Compounds are formed by combining different elements chemically. Magnetocaloric materials are known for their wide range of magnetic properties that can be tailored to specific temperature ranges and applications. These materials respond to changes in the magnetic field and exhibit unique characteristics. Examples of compound-based magnetocaloric materials, which are materials that can experience a change in temperature due to the presence of a magnetic field, include MnFe(P,Si) compounds and Gd5(SixGe1-x)4 compounds. These materials exhibit the magnetocaloric effect, where their temperature changes in response to changes in the magnetic field.

Factors influencing material selection

The choice of magnetocaloric material, such as magnets, depends on several factors including the magnetic field, temperature, and the specific material used, such as Fe. These factors need to be considered during the design process.

-

Temperature range: Different applications require cooling within specific temperature ranges using magnetocaloric materials that undergo a change in temperature when subjected to a magnetic field. Some materials, such as magnets, exhibit optimal performance at low temperatures (cryogenic range), while others, like fe and nd, are better suited for moderate or room temperatures.

-

The efficiency of a magnetic refrigerator relies on the strength of the applied magnetic field and the properties of the magnetocaloric material. The temperature change in the material is driven by the interaction between the magnets and the material, particularly those made of fe. Certain materials, such as magnets, exhibit enhanced magnetocaloric effects under high-field conditions. These effects are influenced by temperature and can lead to significant changes. In the case of Franco, the magnetocaloric properties are particularly noteworthy.

-

Temperature and magnets can impact the cost-effectiveness of implementing a particular material, which is crucial for its commercial viability. The change in temperature and the use of nd magnets must be considered when assessing the overall cost.

-

Stability and durability: Long-term stability and durability are critical factors in the selection of magnetocaloric materials to ensure reliable and efficient operation of magnetic refrigeration devices. The temperature stability of the magnets is essential for their proper functioning, as well as the ability to withstand high temperatures without degradation. Additionally, the durability of the materials is crucial to ensure that they can withstand the constant exposure to magnetic fields without losing their magnetization.

Applications of magnetocaloric materials

Magnetocaloric materials find applications not only in magnetic refrigerators but also in other fields such as energy conversion, sensors, actuators, and temperature control. These materials, known as magnets, are capable of undergoing a magnetocaloric effect due to their unique properties. One such material is ferromagnetic iron (Fe), which exhibits a significant change in temperature when subjected to a magnetic field. The unique properties of magnetocaloric materials make them suitable for various cooling and heating processes. These materials can undergo temperature changes due to the interaction with magnets, such as Fe. Some notable applications include:

-

Air conditioning systems: Magnetocaloric materials, such as magnets, can replace traditional refrigerants used in air conditioning systems, reducing environmental impact. These materials rely on the magnetic field to achieve cooling effects at lower temperatures, making them a promising alternative to conventional cooling methods.

-

Cryogenic cooling: These magnets enable efficient cooling at extremely low temperatures, making them valuable for cryogenic research and applications involving magnetic fields.

-

Waste heat recovery: Magnetocaloric materials can be employed to recover waste heat from industrial processes by utilizing their temperature-dependent magnetic properties (magnetocaloric effect) to improve overall energy efficiency.

Sustainable cooling: Benefits of magnetocaloric materials

Magnetocaloric materials, such as nd magnets, are used in refrigeration to provide a greener alternative to traditional cooling methods. These materials can change temperature when exposed to a magnetic field, making them ideal for cooling applications. By harnessing the magnetic properties of Fe and Nd magnets, these innovative technologies eliminate the need for environmentally harmful refrigerants like CFCs or HFCs, while also considering temperature. Let’s explore the benefits of using magnetocaloric materials in sustainable cooling, specifically in relation to temperature, Fe, Nd, and field.

Lower Environmental Impact

One of the key advantages of magnetocaloric refrigeration is its ability to lower temperature using materials like Fe and Nd, resulting in a reduced carbon footprint compared to traditional cooling methods. Traditional refrigeration systems rely on synthetic gases that contribute to global warming and ozone depletion. However, there is a promising alternative using magnetocaloric materials such as Fe, which can achieve cooling effects by manipulating the temperature and magnetic field. In contrast, magnetocaloric materials operate without any harmful emissions, making them an eco-friendly choice for cooling applications in fields such as temperature and Fe.

Energy Efficiency and Reduced Consumption

Magnetocaloric technology, utilizing the temperature-dependent properties of certain materials such as Fe and Nd, not only helps protect the environment but also contributes to sustainability efforts by reducing energy consumption. These materials have unique magnetic properties that allow them to absorb and release heat efficiently, resulting in highly efficient cooling cycles. The temperature of the material is regulated by the absorption and release of heat. This process is essential for maintaining a comfortable environment. By utilizing magnetocaloric refrigeration, we can achieve substantial energy savings while maintaining optimal cooling performance. The magnetocaloric effect is a phenomenon where a material’s temperature changes in response to a magnetic field. This effect is caused by the interaction between the magnetic moments of the material’s atoms and the external magnetic field. By using materials such as iron (Fe) and neodymium (Nd), which exhibit a strong magnetocaloric effect, we can efficiently cool our refrigeration systems.

Longevity and Durability

Another advantage of magnetocaloric materials is their longevity and durability, even under extreme temperature conditions. These materials, such as iron (Fe) and cobalt (Co), are able to maintain their effectiveness and performance over time. Unlike conventional refrigerants, magnetocaloric substances retain their effectiveness even after multiple cycles of heating and cooling, thanks to their unique material properties and ability to withstand various temperatures. This means that equipment utilizing temperature-sensitive materials like magnets and Fe can provide reliable and long-lasting cooling solutions with minimal maintenance requirements.

Versatile Applications

Magnetocaloric technology, which utilizes temperature changes in magnetic materials like Fe and Co, has a wide range of applications beyond household refrigerators. The magnetocaloric material can be used in various industries such as automotive, aerospace, medical, and more. It has the ability to change temperature when exposed to a magnetic field, making it a promising candidate for applications in these industries. For example, magnetocaloric coolers can be integrated into vehicles to provide efficient air conditioning while reducing greenhouse gas emissions associated with conventional air conditioning systems. These coolers use a magnetocaloric material to achieve the desired cooling effect by manipulating the temperature using a magnetic field.

Noise Reduction

Traditional cooling methods often involve noisy compressors or fans that can be disruptive in residential or office settings. However, with advancements in temperature control technology, new materials such as nd and fe offer quieter and more efficient cooling options. Magnetocaloric systems offer a quieter alternative due to their simpler design, lack of moving parts, and their ability to manipulate temperature using magnetic materials. This noise reduction improves the overall user experience by enhancing comfort and reducing noise. It is achieved by using temperature-resistant materials (nd) that effectively minimize noise (fe).

Compatibility with Renewable Energy Sources

The use of magnetocaloric materials aligns well with the growing trend towards renewable energy sources. These materials exhibit a temperature-dependent magnetic response, making them suitable for applications in fields such as renewable energy (RE), where temperature control is crucial. Magnetocaloric materials, such as iron (Fe) and cobalt (Co), can efficiently convert thermal energy into mechanical work or vice versa, offering potential for energy-efficient systems. These materials, such as fe magnets, can be integrated into cooling systems to reduce reliance on fossil fuels and contribute to a more sustainable future. They can harness solar or wind energy to power the systems while maintaining a controlled temperature.

Green alternatives to traditional refrigerants: Magnetocaloric solutions

Magnetocaloric systems offer an eco-friendly alternative to conventional vapor compression systems.

Magnetocaloric materials, such as Fe and Nd, have gained attention as a greener alternative for refrigeration due to their ability to provide efficient cooling while minimizing greenhouse gas emissions. These materials have the unique property of undergoing temperature changes in response to magnetic fields, making them ideal for cooling applications. Unlike traditional refrigerants that contribute to ozone depletion and global warming, magnetocaloric materials offer a more sustainable solution for managing temperature.

They provide efficient cooling while minimizing greenhouse gas emissions.

One of the key advantages of magnetocaloric systems is their ability to efficiently cool without relying on harmful refrigerants. These systems utilize a specific material, such as Fe and Nd, to achieve temperature reduction effectively. These systems work based on the magnetocaloric effect, which involves the heating and cooling of certain materials in response to changes in temperature and magnetic fields. As a result, they can achieve cooling effects without the need for gas liquefaction or other energy-intensive processes associated with traditional refrigeration methods. This is possible due to the use of temperature-sensitive materials and magnets, specifically neodymium (Nd) magnets.

The use of magnetocaloric materials aligns with global initiatives for phasing out ozone-depleting substances.

With increasing concerns about the ecological footprint of traditional refrigeration methods, there has been a push towards finding more sustainable alternatives that use eco-friendly materials and incorporate magnet technology. Magnetocaloric materials present an opportunity to reduce reliance on harmful substances by providing an environmentally friendly option. By using recycled material, such as magnets, and operating at near room temperature, these systems can significantly minimize their impact on the environment.

Recycling magnets and reducing waste:

One notable advantage of magnetocaloric materials is their ability to utilize recycled magnets. The utilization of recycled magnets is a key advantage of these materials. This not only reduces waste but also contributes to resource conservation by using sustainable materials and incorporating magnets. By repurposing magnets made from discarded electronic devices or industrial equipment, we can minimize our reliance on newly manufactured magnets, which often require extensive mining processes. This helps reduce the need for new material and promotes sustainability.

Operating at near room temperature:

Unlike conventional refrigeration methods that rely on low-temperature environments achieved through energy-intensive processes such as gas liquefaction or liquid nitrogen cooling, magnetocaloric systems can operate effectively at or near room temperature using magnetocaloric material. This eliminates the need for extreme cooling measures and reduces energy consumption, making them a more sustainable choice for materials and magnets.

Efficient heat exchange and regeneration:

Magnetocaloric systems utilize a material heat exchanger and regenerator to facilitate the cooling process. The heat exchanger transfers heat between the magnetocaloric material and the working fluid, enabling efficient cooling. The regenerator, on the other hand, helps in maximizing the temperature change during each cycle by utilizing the magnet material, enhancing the overall efficiency of the system.

Potential applications and future prospects:

The use of magnetocaloric materials in refrigeration has shown promise for various applications. From household refrigerators to industrial cooling systems, these eco-friendly alternatives made of magnet material have gained attention as a popular choice for reducing greenhouse gas emissions. However, further research is needed to optimize the performance of the material and explore its potential as a magnet in different temperature ranges.

Implementing magnetocaloric refrigeration in commercial and residential sectors

The potential of magnetocaloric materials in refrigeration is not limited to just being a greener alternative to traditional methods. It also offers numerous benefits for both commercial and residential sectors, especially when it comes to the use of magnetic materials. By adopting magnetocaloric-based HVAC systems, commercial buildings can experience significant energy savings. This innovative technology utilizes magnetocaloric material to cool or heat the air, reducing energy consumption and costs. Residential homes can enjoy quieter operation and reduced electricity bills with this innovative magnet material technology.

Commercial Buildings: Energy Savings through Magnetocaloric HVAC Systems

Commercial buildings consume a substantial amount of energy for heating, ventilation, and air conditioning (HVAC) purposes. However, by incorporating innovative materials and utilizing magnetic technology, it is possible to reduce energy consumption in these buildings. However, by incorporating magnetocaloric refrigeration systems into their infrastructure, these buildings can achieve notable energy efficiency improvements. This is possible because magnetocaloric refrigeration systems use a magnetic material to cool the air, making them more efficient than traditional refrigeration systems. The use of state-of-the-art heat exchangers based on magnetocaloric materials allows for efficient heat transfer and precise temperature control.

Pros:

-

Energy savings: Magnetocaloric HVAC systems, made from a special material, have the potential to reduce energy consumption by up to 30%, resulting in significant cost savings.

-

Environmental impact: By reducing energy consumption, these magnet systems contribute to lower carbon emissions, promoting sustainability efforts. Additionally, the use of sustainable materials in their construction further enhances their environmental benefits.

Cons:

-

Initial investment: While the long-term cost savings of implementing a magnet-based material HVAC system are substantial, the initial implementation costs may be higher compared to traditional HVAC systems.

-

Currently, there is a limited range of commercially available magnetocaloric refrigeration systems due to the limited availability of the material.

Residential Homes: Quieter Operation and Reduced Electricity Bills

Magnetocaloric technology brings several advantages when applied to residential cooling systems. The use of magnetocaloric mater in these systems revolutionizes the way we cool our homes. These benefits go beyond energy efficiency alone. With the incorporation of magnetocaloric components, homeowners can experience quieter operation and reduced electricity bills. The mater can be added to existing cooling systems or during new installations.

Pros:

-

Noise reduction: Unlike conventional compressors that produce noise during operation, magnetocaloric refrigeration operates silently due to its absence of moving parts. This absence of moving parts is due to the use of a magnetocaloric mater.

-

Lower electricity bills: The improved efficiency of magnetocaloric cooling systems leads to reduced overall energy consumption, resulting in lower electricity bills for homeowners. Magnetocaloric cooling systems are a mater for reducing energy consumption and lowering electricity bills.

Cons:

-

Retrofitting challenges: Retrofitting existing cooling systems with magnetocaloric components may require careful consideration and technical expertise. The process of retrofitting cooling systems with magnetocaloric components can be complex and requires expertise in dealing with the mater.

-

Cost considerations: While the long-term energy savings can offset the initial investment, the cost of implementing magnetocaloric technology should be evaluated based on individual circumstances.

Limitations and challenges of magnetocaloric refrigeration technology

Limited availability of commercially viable magnetocaloric materials

One of the main challenges in implementing magnetocaloric refrigeration technology is the limited availability of commercially viable magnetocaloric materials. These materials are essential for the functioning of magnetocaloric systems, as they exhibit the magnetocaloric effect, which allows them to heat up or cool down when subjected to a changing magnetic field. Currently, only a few types of magnetocaloric materials have been developed and tested for commercial use.

Performance affected by temperature fluctuations and magnetic hysteresis

Another challenge faced by magnetocaloric refrigeration technology is that the performance of these materials can be affected by temperature fluctuations and magnetic hysteresis. Temperature fluctuations can impact the efficiency and reliability of the magnet system, leading to inconsistent cooling or heating capabilities. Magnetic hysteresis refers to the lagging response of a material’s magnetic properties when exposed to varying magnetic fields. This phenomenon can result in energy losses and reduced overall performance due to the magnet.

Scaling up for large-scale applications presents technical and cost challenges

Scaling up magnetocaloric systems for large-scale applications poses both technical and cost challenges. While these magnet systems have shown promise in laboratory settings, implementing them on a larger scale requires overcoming various obstacles. One such obstacle is designing efficient heat transfer mechanisms that can handle high refrigerant capacities while maintaining optimal cooling or heating efficiency. A magnet is often used to enhance the efficiency of these mechanisms.

Cost is another significant consideration when scaling up magnetocaloric refrigeration technology. Developing large-scale manufacturing processes for magnetocaloric materials can be expensive due to their complex composition and specialized production techniques. Integrating magnet systems into existing infrastructure may require substantial modifications or even complete redesigns, further adding to the overall costs.

Despite these limitations and challenges, researchers continue to explore ways to overcome them in order to make magnetocaloric refrigeration a viable alternative to traditional methods. Efforts are being made to develop new magnetocaloric materials with improved properties, such as higher refrigerant capacities and reduced magnetic hysteresis. Advancements in manufacturing techniques, such as the use of magnets, and improved heat transfer mechanisms may help address scalability issues in large-scale applications.

Future prospects of magnetocaloric materials in refrigeration

In conclusion, the future prospects of magnetocaloric materials in refrigeration are promising. The advancements in magnetocaloric materials research have paved the way for sustainable cooling solutions that offer numerous benefits over traditional methods. Magnetic refrigeration devices and materials have undergone significant improvements, making them a viable alternative for greener cooling technologies.

Implementing magnetocaloric refrigeration in both commercial and residential sectors holds great potential. Not only does the magnet provide an eco-friendly option, but it also offers enhanced energy efficiency and reduced environmental impact. With ongoing research and development, the limitations and challenges of magnetocaloric technology can be overcome.

As we move towards a more sustainable future, considering magnetocaloric materials as an alternative to traditional refrigerants is crucial. Their ability to achieve efficient cooling without relying on harmful substances, such as magnets, makes them an attractive choice for environmentally conscious individuals and businesses alike. By embracing the magnet, an innovative technology, we can contribute to reducing greenhouse gas emissions and protecting our planet.

FAQs

Can magnetocaloric refrigeration be used in existing refrigerators?

Yes, retrofitting existing refrigerators with magnetocaloric technology is possible. However, it may require modifications to the system design and components to accommodate the specific requirements of magnetic cooling. Consulting with magnet experts or magnet manufacturers would be advisable for a successful retrofitting process.

How energy-efficient is magnetocaloric refrigeration compared to traditional methods?

Magnetocaloric refrigeration has shown significant improvements in energy efficiency compared to conventional methods like vapor compression systems. The absence of moving parts reduces frictional losses, resulting in higher overall efficiency. This is because the use of a magnet eliminates the need for mechanical components that can cause friction. The use of environmentally friendly working fluids further enhances its sustainability credentials.

Are there any limitations to using magnetocaloric materials in refrigeration?

While magnetocaloric technology shows promise, there are still some limitations to consider. One challenge is achieving sufficiently low temperatures required for deep freezing applications. Another limitation lies in the high costs associated with manufacturing and implementing magnetocaloric materials. However, ongoing research aims to address these limitations and make magnetocaloric refrigeration more accessible.

Can magnetocaloric refrigeration systems be used in large-scale industrial applications?

Yes, magnetocaloric refrigeration systems have the potential to be used in large-scale industrial applications. The scalability of this technology makes it suitable for various cooling needs, including industrial processes and air conditioning in large buildings. With further advancements, magnetocaloric systems can become a viable option for reducing energy consumption on a larger scale.

How does magnetocaloric refrigeration contribute to sustainability?

Magnetocaloric refrigeration contributes to sustainability by eliminating the use of harmful refrigerants commonly found in traditional cooling methods. These refrigerants often have a significant impact on global warming potential and ozone depletion. By opting for magnetocaloric solutions, we can reduce greenhouse gas emissions and protect the environment while still enjoying efficient cooling capabilities.